Modular multi-channel temperature control system FP1600

- up to 128 control circuits

- Modular structure

- PROFINET communication to the SIMATIC S7

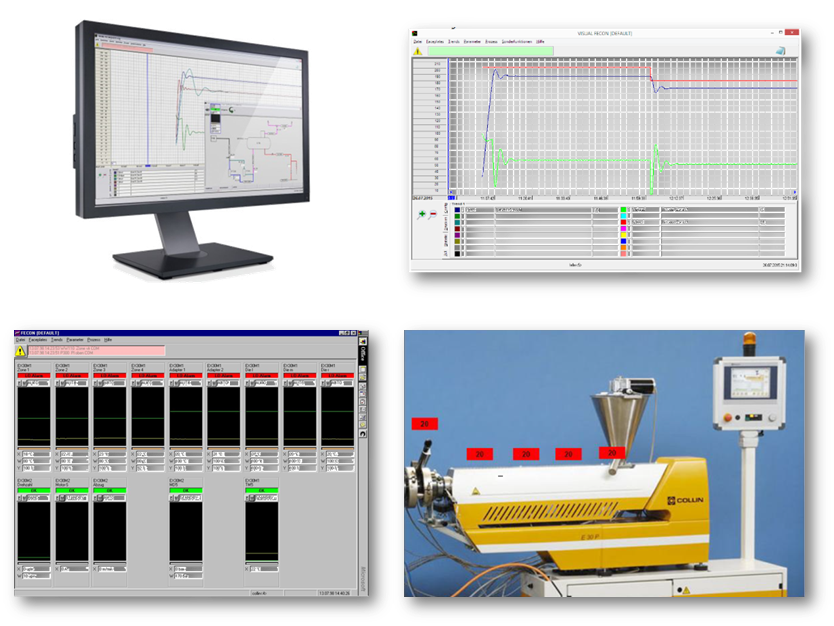

- Powerful operating and SCADA software

- Variable system integration

- Powerful functions

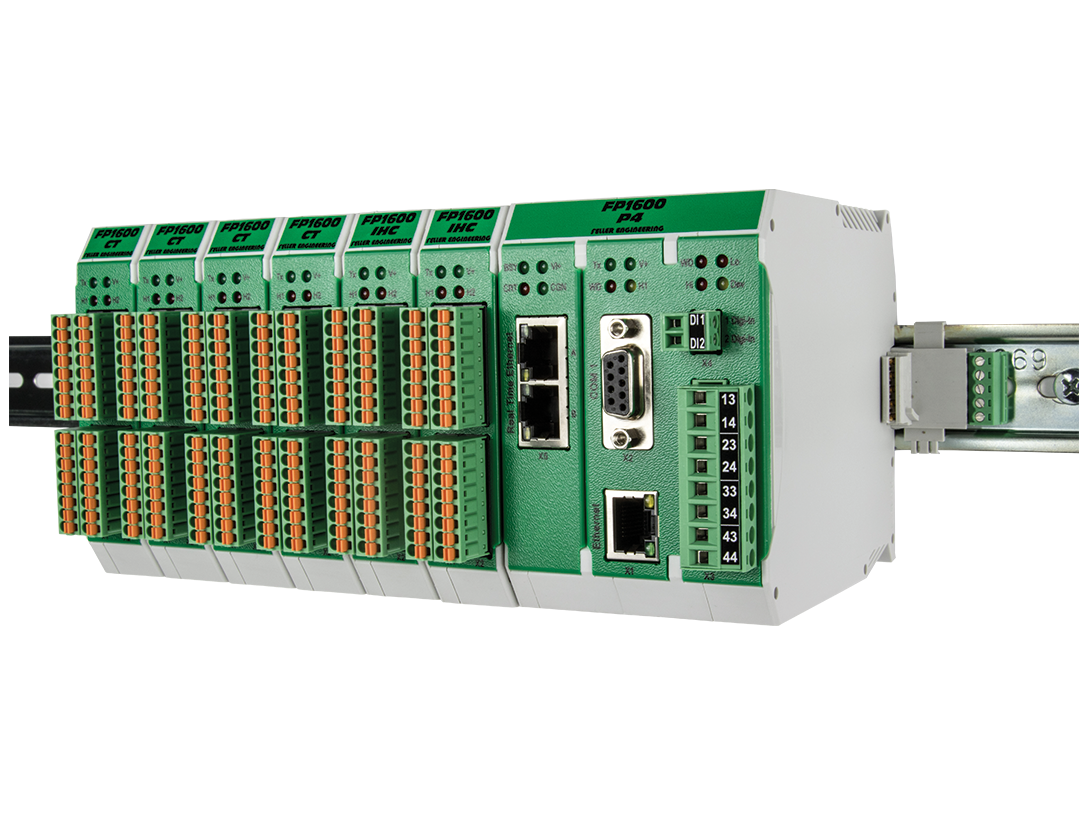

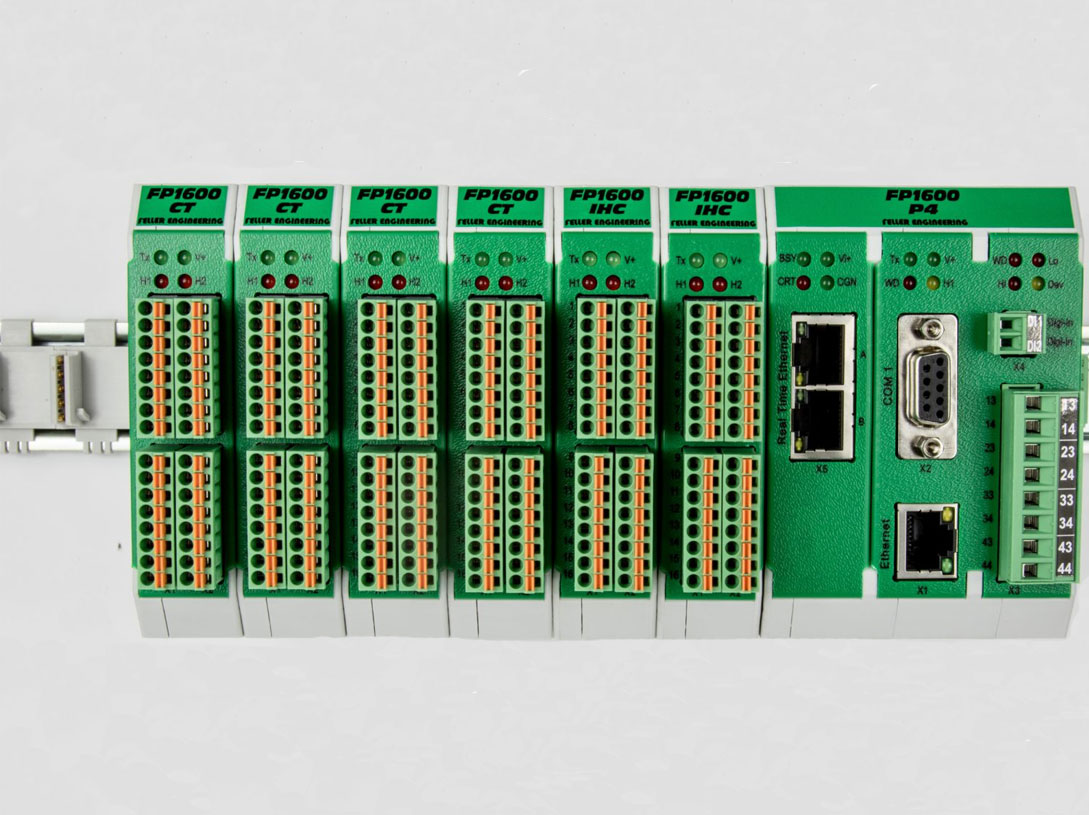

Modular system structure

The decades of experience of Feller Engineering in the field of temperature control technology forms the basis for the FP1600 multi-circuit control system. Constantly further developed by customer requirements, a powerful system was created that can be adapted to the most varied applications due to its modularity.

To do this, depending on the objective of the task, different central units and input and output modules are available that are easily strung together on a DIN rail with bus adapters.

Communication

The core of each application is the central unit with processor for up to 128 control circuits and communication interfaces for higher level systems. The system offers as standard RS485 and Ethernet to network several controllers, for remote diagnosis via the integrated web server or to connect to the higher level SCADA system, Visual Fecon, for easy configuration and display.

Another version also has a real time Ethernet interface with PROFINET and Sercos III protocols. This enable multi-channel controllers to be connected to automation systems.

A variety of modules

The list of available modules shows the variety of the control system. The system can be configured individually with the following click-on modules:

Powerful control functions

The system can be used in many different applications due to the powerful control functions. The most important functions are:

Voltage

24VDC, supply via a terminal system in a DIN rail

Tolerance

+/-10%

Power consumption

depending on expansion stage, see documentation

P, PI, PD or PID, self-optimising depending on requirements

Summary for all zones

1x LO-alarm

1x HI-alarm

1x DEV-alarm

1x WATCHDOG

max. power per contact

3A

max. voltage per contact

250VAC, 30VDC

FE3-Bus, MODBUS TCP, MODBUS RTU, udp, ftp, http, telnet

optional: PROFINET, SERCOS III

RS485 insulated, ETHERNET

Optional: 2 x real time Ethernet with integr. switch

to the internal communication of the modules

CAN-Bus, via terminal system in a DIN rail

max. cable length

100m

To store parameters on the SD memory card.

0 .. 50°C

depending on the module

22,5 x 100 x 115mm

45 x 100 x 115mm

67,5 x 100 x 115mm